'Car/Engine'에 해당되는 글 45건

- 2008.10.26 [CAR] Gen Info

- 2008.10.26 [CAR] DLC

- 2008.10.26 [CAR] Engine Family Information

- 2008.10.26 [CAR] OBD Sc

- 2008.10.26 [CAR] How do I check the fluid level on my Tranny?

- 2008.10.26 [CAR] Transmission filter replacement and partial fluid swap?

- 2008.10.26 [CAR] faulty transmission range sensor

- 2008.10.26 [CAR] I have transmission problems ( ECU code: P1870).

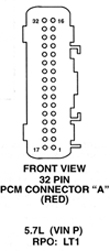

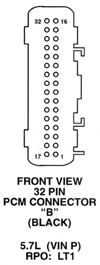

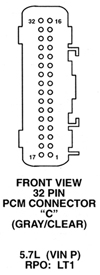

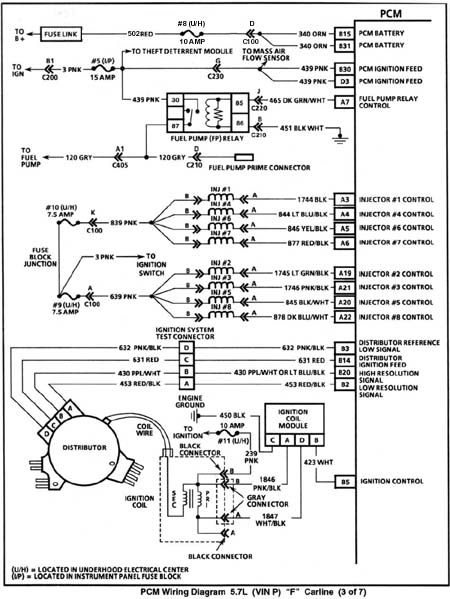

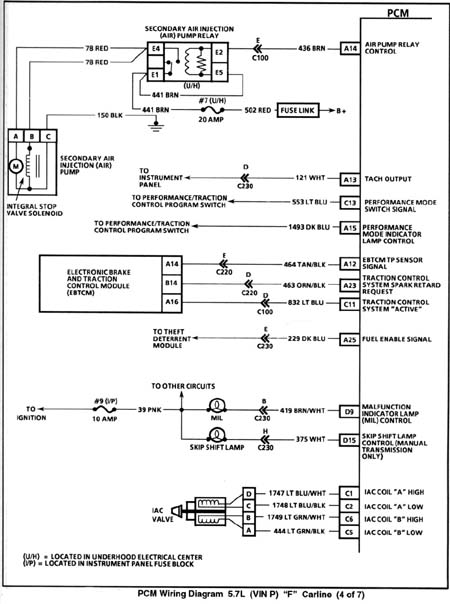

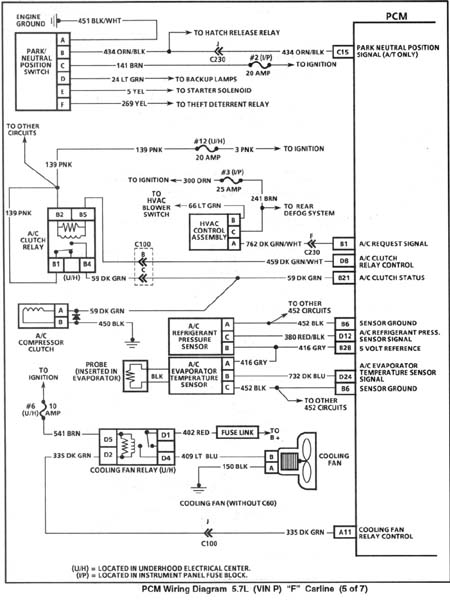

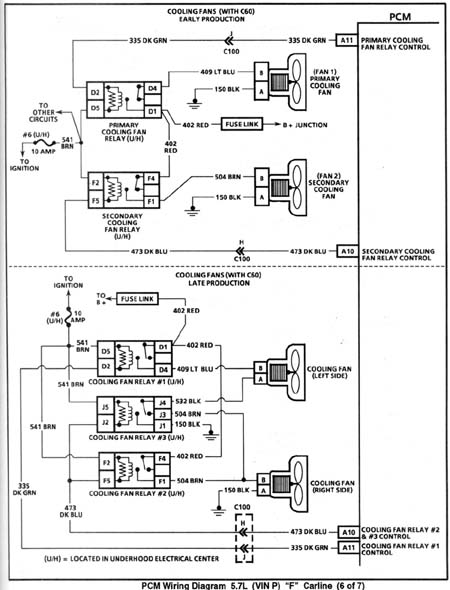

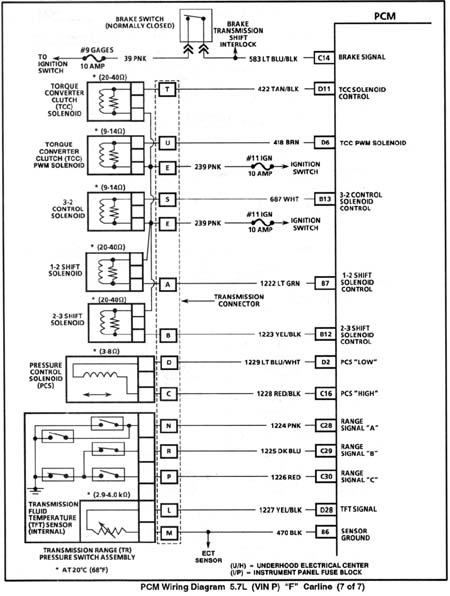

- 2008.10.26 [CAR] About PCM

- 2008.10.26 [CAR] Check Trans and Engine light (code P1870)

Jason Cromer: 800-498-2301 Sam Taylor Buick/Cadillac, Ft. Walton Beach, FL

The sensor resides on the RH side (passenger) of the engine block, in the coolant drain location. The F-body uses only one sensor. Other body platforms may use two sensors on their LT1 applications.

On the 1994-1997 LT1 F-body PCM, there is a replaceable module that receives the knock signal. 1993 ECM's have the receiver circuitry built-in to the computer and have no replaceable module.

You may have heard about an LT4 knock module. This module came from the 1996 LT4 Corvette, that had roller rockers as standard equipment. The LT4 module is tuned to allow for the noise the rockers make (not perceiving it as knock). If you have similar valvetrain modifications on your LT1, it may be a good idea to swap to the LT4 module to reduce the chance of "false knock" (knock not related to detonation).

The LT4 module can be used on 1994-1997 engines (OBD-I and II) and no change of the knock sensor is needed (even though the sensors changed in 1996). There is no specific LT4 knock sensor. However, there are differences in the impedance of the sensors between OBD-I and II as listed in the testing section below. You must use the sensor that is matched to your OBD type (or have a wiring modification as frequently done in an OBD type swap situation).

Key OFF. Connector off at the knock sensor. Measure the resistance between the KS terminal and ground. Resistance should be between 3300-4500 ohms (OBD-I) or 93k-107k ohms (OBD-II). If it is not, the sensor is faulty or the sensor is not making good contact with the block. Try another resistance reading from the sensor terminal to the outside metal of the sensor body.

If all that is good, it might be a faultly knock module (in case of 94-97) or a problem with the computer, itself.

OBD-I (1993-1995) knock sensor GM PART # 10456126 ACDelco #213-96

OBD-II (1996-1997) knock sensor GM PART # 10456287 ACDelco #213-325

Note: It is possible that the LOW COOLANT lamp may come on after this procedure. It should go out after the engine has gone through several heat and cool cycles. Make sure that the remote reservoir is kept at the proper level. If the light seems to come and go, make sure the level in the remote reservoir is proper. Normal operation of the cooling system often causes coolant from the radiator to overflow into the remote reservoir. As the engine cools down, the radiator creates a vacuum and pulls this coolant back into the radiator. The piping from the neck of the radiator to the reservoir must be air tight for this to occur. Since these cars are getting older, it is not uncommon to get a small leak in the pipe that goes under the battery. Acid wears away at the pipe until it makes a hole. Even a small hole is enough to cause problems. A telltale sign is a small amount of coolant under the right front of the car after it is parked a while. Usually, only taking out the battery will reveal where it is coming from, because it slowly drips on the splash panel underneath and may travel along to another area to drip off.

If the lamp is coming on for no apparent reason (you have verified coolant level is fine-that is, checked the level in a cold radiator and verified you have the proper level in the remote reservoir), you have just a few choices: The thermostat only has control of opening temp to allow coolant flow, after that it does nothing but cause a predetermined amount of restriction in the flow. To make the most of the lower temperature thermostat, it should be accompanied by reprogramming of the fans, so that they will come on at a lower temperature. This will help to maintain a lower overall temperature in all driving conditions (especially when stopped in traffic). It is not mandatory that you do this and a 160?can be installed by itself with no other modification. The hydraulic lifter has an internal plunger that has a specific amount of travel. On stock engines, the purpose of preload is to compress the plunger so the pushrod will be riding on a "cushion" (acts like a shock absorber). With stock lifters, turning the rocker nut another ?to ?turn, will normally put you in the ballpark for quiet operation without being too tight and the adjustment should last a long time. Specific lifters like the Comp Cams "Comp R's", have less internal travel. ?turn preload is more than plenty, with 1/8 or just barely any preload being better for high revving engines. Comp actually recommends .002-.004 preload on a warm engine. There are several methods for setting the lash with the engine not running and are listed below. Read through them all. You might prefer one method over another. They all accomplish the same thing. When the arrow is at 12 o'clock you will be at either #1 or #6 TDC. You might have trouble identifying whether #1 or #6 is at TDC when the crank arrow is at 12 o'clock. Probably the easiest way is to look over the other valves or lifter positions. Compare them to the charts below, showing which can be adjusted. Any valve that can be adjusted should be UP (closed) and the lifter/pushrod should be down. Valves that are not to be adjusted will be in varying degrees of being open or DOWN (lifters/pushrods UP). I used to recommend looking at the valves on the #1 and #6 cylinders, but sometimes it can be difficult to tell by those cylinders only. After looking at the charts below and your valves or lifters/pushrods, you should have it figured out rather quickly.

Continue the above procedure for each cylinder until all valves are adjusted to the same amount of preload. This procedure will work for any hydraulic lifter cam with adjustable rocker arms. Refer to this diagram posted above if you need visual reference. If you don't see the proper ac voltage the problem could be the optispark, the harness to the optispark, the PCM or any of the wiring in between. Visually inspect all the connections you can get to for poor contact or corrosion.

edited 5/16/2004

Normal pressure when the engine is not running and lines have been pressurized is 41-47 psi. This same pressure should be observed at wide open throttle (WOT). WOT can be simulated by removing the vacuum hose to the regulator at idle. At idle (because of the effect of the vacuum to the regulator) pressure will be less than what you observe with the vacuum line off. There may be anything from a 3 to 10 psi difference. Note: any indication of fuel in the vacuum line to the regulator, means the regulator is leaking and should be replaced. Check the line for fuel or the smell of fuel.

To fully determine that you don't have a pressure drop off during actual WOT situations, you should tape the gauge to your windshield and take it for a test run. This will tell you if the pump can meet actual fuel flow demands at pressure and not just at a simulated WOT condition (as when removing the vacuum to the regulator).

When you have a gauge connected and the pressure looks initially good and then bleeds off quickly when you shut the engine off, you can do a couple of tests to help you figure out where the pressure loss is.

What the factory manual says to temporarily install, is a set of "fuel line shut off adapters" (probably something the normal guy is not going to have available). You remove the fuel lines from the rail and connect these valves in between. This lets you shut off either side of the lines for testing.

You can do the same thing by pinching the flexible lines to shut them off, but risk breaking them. You might be able to do it (your risk) by using a needle nose vise grips and putting some scrap hose as cushions on the jaws. Then use that to clamp off the line just enough to seal it. Obviously, this is not the best way to shut off the lines and could result in breakage. Heat and age can make the hoses brittle. If you don't want to risk it, don't. It's just a suggestion.

You can use the fuel pump prime connector for pressurizing the system (jumper 12v to it to run the pump).

Watch your gauge as you jumper the prime connector. When you have good pressure remove the jumper and clamp off (or use shut off valve) the fuel supply line (3/8 pipe). If pressure holds, you have a leak on the feed line somewhere before it gets to the clamp (or shut off valve) or at the check ball in the pump. If it still goes down, release your clamp (or open shut off valve). Pressurize the system again, then remove the jumper and this time clamp (or shut off) the return line (5/16 line). If pressure holds, then the regulator is faulty. If pressure does not hold, you need to locate leaky injector(s).

If you can't tell a leaky injector from reading the plugs, you can look and see if injectors are leaking by removing the fuel rail screws and pull the rail and all the injectors up, so you can see under them. Leave them over the injector ports. Pressurized the system and look under the injectors to see if any are dripping. Typically, when the gauge reads: Avoid running your car out of fuel! The fuel also acts to keep the pump cool. Running out of fuel can trigger a pump failure.

If you are having a problem not related to the "normal" way the gauge acts as stated above, there are some things you can check. approximate: To test back to the gauge, ground the purple wire on the body side of the connector back toward the gauge (key ON). The gauge should read empty. With the connector unplugged and no ground applied, the gauge should read full. It is NOT recommended to to push or pull on the pintle of an IAC that has been in service. The force required can damage the threads on the worm drive. Also, do not soak the IAC in any liquid cleaner or solvent, as damage may result. When installing a new IAC, you may move the pintle to match the measurement of the old one. The force required to move a NEW valve will not cause damage to it. Use engine oil to lubricate the o-ring. Tighten attaching screws to 27 lb. in. An easy way to tell what part of the system may have trouble is to go to the vacuum check valve and test the lines back to the mode selector, intake manifold and to the vacuum tank. The check valve often cracks and is the source of a leak, so be sure to inspect and/or test it.

A hand held vacuum pump (like a Mityvac), makes testing pretty easy (your lungs can be used as an alternate vacuum source ;-) ). At the check valve, remove the hoses one at a time and apply vacuum to each and see if it holds. The line to the intake manifold will have to be removed at the manifold and plugged back toward the check valve for you to test the line for leaks. If you find a leak on a particular hose, you will have to trace out the cause on that section.

1996-1997 f-body cars have two cats.

1993-1995 LT1 f-body cars are all OBD-I (regardless of how many cats they have).

1993 LT1 f-body cars can flash trouble codes by shorting 2 pins in the DLC and observing the Service Engine Soon lamp (like most earlier model GMs). 1994 and later must use a scan tool. The computers changed from ECM (Engine Control Module) in 1993 to PCM (Powertrain Control Module) in 1994 and later (adding electronic transmission control). Though 1993 and 1994 were both OBD-I, they used different computers. 1993s used the replaceable chip type (PROM), while 1994 and up used flash memory for storing the program (EEPROM).

1996-1997 LT1 f-body cars are OBD-II.

1993 LT1 f-body cars have two 1 wire, non-heated O2 sensors. 1994-1997 have two 4 wire, heated O2 sensors (with 1996-97 cars having two additional rear (post cat) O2s to comply with OBD-II). On the f-body, front O2s use a flat connector. When rear O2s are present, they use a square connector.

The only 1995 f-body engine that is OBD-II is the 3.8L V6 that came out during the model year (replacing the 3.4L V6 that was OBD-I).

RPO NA5 = Federal Emissions System

RPO NB6 = California Emissions System

![]()

Wholesale prices and no rip-off shipping.

Dal Slabaugh: retired as of 12/1/2007

Best wishes and thanks for all the years of service to the GM community!

![]()

The Keyless Entry Receiver is capable of accepting Vehicle Access Code (VAC) programming from any two random Transmitters. One or two Transmitters can be programmed. When two Transmitters are programmed, they must be programmed during the same program sequence, one after the other but not simultaneously. The Transmitter is manufactured with a permanent VAC combination (one of over 4 billion combinations) that cannot be changed for the life of the Transmitter. The Receiver can only be programmed by the Transmitter when it is powered at the Battery input at connector C2 terminal "F" and the program input line is grounded to connector C1 terminal "A".

Programming procedure:

Important

![]()

NOTE: Always program both transmitters when replacing a lost or damaged transmitter. The first transmitter code programmed will always be in both memories until a second transmitter is programmed within the same sequence.

![]()

Action

Normal Results

![]()

The BCM can display a series of DTCs, when it is placed in the diagnostic mode. These DTCs are displayed as flash codes through the "Security" indicator lamp on the instrument cluster (much like the 1993 and earlier OBD-I codes are flashed on the SES lamp). During normal operation, if the BCM detects a fault on a monitored circuit, there will be no flashing or any indication that a fault has occurred, though you might detect a system malfunction. The system faults will be recorded as "Current" or "History". A "Current" DTC means that the condition was present when the diagnostic mode was entered. A "History" DTC means the condition has occurred since the BCM was installed in the vehicle, but may not be present currently. If a "Current" DTC is present, the associated "History" DTC will always be present. When you work on systems associated with the BCM, you should always check for DTCs.

Diagnostics is entered by performing the following steps:

The BCM will begin to flash DTCs 4 seconds after entering the diagnostic mode, from the programming mode. Each flash of the "Security" indicator lamp on the I/P represents a number. For example, one flash followed by two quick flashes represents a code 12. Each code is displayed 3 times before the next code is displayed. Any DTCs present are displayed in numerical order. Once the last code is displayed, the list begins over again with the first code. The display continues until the diagnostic mode is exited.

History DTCs are those indicating that the BCM previously detected a fault with later disappeared. Any DTC that has a 3 as its first digit is a History DTC. The reason could be that the fault is a true intermittent only happening occasionally or that the system which the DTC monitors is not currently being operated.

If a visual physical check does not find the cause of the concern, the vehicle can be driven with a DVM connected to the suspected circuit. An abnormal voltage or resistance reading when the concern occurs indicates the concern may be in that circuit.

"Current" DTCs (21-25) will remain stored and display as long as the BCM detects the fault criteria. "History" DTCs (31-35) can be cleared by pressing the door lock switch for a period of 4 seconds while the BCM is in the diagnostic mode. The chime will sound 3 times at the end of the 4 second period as a confirmation that the DTC(s) have cleared.

BCM Schematic for 1996 (1997 probably the same).

BCM DTC

DESCRIPTION

12

Begin Diagnostic Display

21/31

Courtesy Lamps Feed (Circuit Shorted to Ground)

22/32

Courtesy Lamps Return (Circuit Shorted to Battery +)

23/33

Retained Accesory Power (Circuit Shorted to Ground or Battery +)

24/34

Fasten Seatbelt Indicator Lamp (Circuit Shorted to Ground or Battery +)

25/35

Security LED present (with AU6 only)

41

Last Transmitter Message Received Valid (with AU0 only)

42

Last Transmitter Message Received had Invalid ID (with AU0 only)

43

Last Transmitter Message Received had Sumcheck Error (with AU0 only)

44

Last Transmitter Message Received had Encryption Error (with AU0 only)

45

Receiver Processing Currently in 20 Second Lockout (with AU0 only)

55

Begin Configuration Display

-## Hardware Configuration

-## Software Configuration

![]()

Flush procedure:

Bleed procedure:

edited 10/10/2004

![]()

튏

튔

Ohms

100

212

177

90

194

241

80

176

332

70

158

467

60

140

667

50

122

973

45

113

1188

40

104

1459

35

95

1802

30

86

2238

25

77

2796

20

68

3520

15

59

4450

10

50

5670

5

41

7280

0

32

9420

-5

23

12300

-10

14

16180

-15

5

21450

-20

-4

28680

-30

-22

52700

-40

-40

100700

Use a Digital Volt Meter (DVM) set to ohms to measure resistance. Note: Use a high impedance meter (at least 10 megohm) when dealing with the PCM. Most modern DVMs will do, but your old analog meter can damage the PCM. It is also a good idea to get a " reference" from the meter you are working with. With the DVM on the ohms scale, touch the two meter leads together and note the ohm reading. It may not always be perfectly zero, but may be within a tenth or two. Now when you take an ohm reading, you will know what the meter will show when there is really no resistance.

If the sensor seems to be ok, you may also need to test at the harness connector for proper lead conditions. Use your test meter set on the dc voltage scale to do this. You will need the key in the RUN position, but don't have to start the car.

Footnote: If you ever have to test the IAT, it operates the same as the two lead coolant sensor. The same temp vs. resistance table above is applicable to the IAT, as well as the +5vdc lead and ground wire at the harness connector.

edited 1/03/2005

![]()

The knock sensor system is used for the detection of detonation. The computer retards spark advance based on the amount of knock received. The knock sensor produces an ac voltage according to the amout of knock. The computer receives the signal and it's programming determines how the computer will change the spark advance.

With the connector off the knock sensor, check for 5v on the harness terminal with key ON. Continue if that is good. If not good, check at pin C8 (1993), D22 (94-97) on back of computer. If voltage is ok at the back of the computer, repair the wire from the computer to the sensor.

edited 7/29/2005

![]()

Drain

It is always a good idea to keep coolant away from the distributor (optispark) to avoid any potential problems when doing any of this work.

Refill

If, after doing work, you want to verify the coolant level for a few days, check that the level is to the top of the radiator neck when the engine is cold. Add coolant to top it off, if needed. Then, also make sure that the level is correct in the remote reservoir.

edited 3/16/2008

![]()

Electric cooling fans attached to the radiator keep the LT1 from overheating when there is little or no air passing through the radiator core (car going very slow or stopped and engine running). It is normal for the temps on the gauge to go up to the middle or past middle of the gauge before the fans kick on. The middle of the gauge is in the range of 210?- 220? With factory programming, the PCM will command low speed fans (or primary fan) "ON" at 226?and "OFF" at 221?and high speed fans (or secondary fan) "ON" at 235?and "OFF" at 230? The fans should come on before it gets to any part of the red zone. (see "dual fan configuration" below about primary and secondary fans)

The f-body LT1 uses a 180?thermostat as stock.

The PCM gets it's temp readings from a sensor that is in the water pump. If the reading the PCM receives is inaccurate, the fans may not come on at the correct time. The PCM also uses this temperature for lookup in fuel calculation tables. If there is a problem that causes the reading to be always low (cold), the PCM will add extra fuel. This can cause hard starting when warm and an overly rich condition when running.

The gauge gets it's information from a sensor that is in the driver's side head. Inaccurate gauge readings can be from this sensor or it's wiring (the wire burned on a header pipe is common). The temp that the PCM sees can be monitored with a scan tool and compared to the gauge reading. They should be close, but don't expect them to be "perfectly" synchronized.

The fans are programmed to come on when the a/c is turned on. A/c Pressure monitoring sensors feed the PCM info and depending on the situation, the PCM may command the fans off for brief periods. Also, when the car reaches sustained higher speeds, the fans may be commanded off so incoming air can flow through the radiator unimpeded and provide the cooling needed.

Fans will also come on when the SES lamp comes on. The PCM does this when certain (most) DTCs are detected to protect the engine from a situation where it may overheat.

There are two versions of the dual fan configuration:

These fans use a two relay architecture that can be seen in the fuse/relay panel that is under the hood.

2 Relay System

PCM Commanded Fan Operation

PCM Wire Color Grounded

Fan Operation

Relay Operated

#1

#2

#3

Primary@226?

Drk Grn @A11

Primary (LH) fan full speed

X

-

n/a

Secondary@235?

Drk Blu @A10

Secondary (RH) fan full speed

X

X

n/a

3 Relay System

Low Speed@226?

Drk Grn @A11

Low Speed (both fans)

X

-

-

High Speed@235?

Drk Blu @A10

High Speed (both fans)

X

X

X

For both fans to operate in either system, both relay leads must be grounded. Grounding only the Drk Blu wire will result in only the RH fan operating at high speed.

Here are some fairly simple things to check for various complaints:

Other cooling issues

![]()

The low coolant sensor is a most common cause of complaint. If it gets dirty, it may cause the lamp to come on when the coolant level is actually ok. Sometimes it fails and no amount of cleaning will fix it. The sensor is only connected to the lamp on the dash. It does not report to the PCM and no DTC's will be set. Because of this, some people choose to simply unplug the sensor to get rid of the annoyance without having to fix it. Unplugging it will make the lamp go out, but you will have to monitor the coolant level yourself. As critical as the coolant is to the LT1, having it working makes sense.

Thermostats and cooling

The temp rating of the thermostat is merely at what temp it will begin to open and allow coolant flow. It is purely a mechanical, temperature reactive device and has no external control or monitoring. A frequent reason behind a lower temp thermostat is to be able to make use of more aggressive spark advance without the engine having any spark knock (detonation or pinging). Excessive spark knock is detrimental to the engine. Spark knock is also monitored by the computer and timing advance is pulled (retarded) by the computer. When timing is retarded, performance and power will decline.

There is a fine line between between enough spark advance for high performance and the penalties for too much. The engine temperature plays a role in that the coolant wicks away heat from the combustion chambers in the head. Higher overall engine temperature results in higher overal combustion chamber temperatures. Installing a lower temperature thermostat alone may actually decrease performance because a certain amount of heat is needed to burn the air/fuel mixture efficiently. If you see a decrease in gas mileage with a lower thermostat, alone, this may be the reason. The trick is to lower the temperatures but add enough timing to increase performance over what it was originally.

An often asked question is "Will my engine stay cooler with just a 160?thermostat?". The answer is yes, as long as there is good air flow across the radiator and the cooling system is working efficiently. Note that engine temps will still climb as they did before when you are stopped (as in traffic). However they may not rise as much, since you are starting out at a lower temperature than before. When you are moving again, it will be possible for the temps to lower more than what the 180?thermostat would previously allow. Cruising down the road, your engine should definitely stay cooler than before. Remember that the rated temperature of a thermostat is the temperature that it begins to open. While crusing on a moderate temperature day, an LT1 will generally run 10?20?warmer than the thermostat temp rating. Make sure you use the correct, long LT1 thermostat as described in the troubleshooting section above.

Something else to consider, is that when the engine gets to ~220?(even before the stock fan ON temp of~226? and you are at MAP loads of 70Kpa or more, the PCM begins to retard the timing. That is one reason why people feel their cars don't run well when they are hot. The GM folks built the retard into the spark tables because when the engine is hotter, there is more chance for spark knock. If you can keep the temperatures from getting up into that range, then you might feel more power when you need it.

Altering the fan ON temps can be done through reprogramming the computer or an aftermarket "fan switch" such as sold by SLP and JET . Manual fan switches can also be wired up to operate the fan relays so that the fans can be operated at any given time the driver wants (like in staging lanes). There are explanations on how to wire the manual switch up on the 'net and there are even a couple of wiring diagrams on my main Tech Page. If you look at the fan schematics, you can probably see that there can be several solutions to operating the fans manually, either by controlling the relays (my preference) or powering the fans directly with 12v and a switch.

edited 9/06/2007

![]()

Do this when the engine is cool (like after sitting overnight or for several hours where there is no residual pressure in the system). This way there will be no need to drain any extra coolant from the system.

8/05/2005

![]()

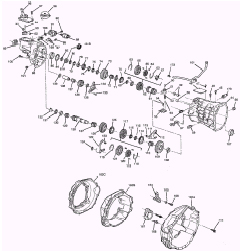

T56 Service Manual (pdf format)

Right click if you want to download and save

Left click to view online

![]()

Zero lash is when you go from having slack between the lifter, pushrod and rocker arm, to the exact point of no slack. The lifter needs to be on the base of the lobe when setting valve lash. When a cylinder is at TDC, both lifters should be at the bottom of their travel (base of the cam lobe).

Gauging zero lash by hand is not an exact science. When setting the valve lash with the engine not running, you can get close enough by doing the "spin the pushrod" method. Loosen the rocker arm until you can feel slack in the pushrod to rocker arm. Spin the pushrod with your fingers while tighening the rocker arm back down. When you BEGIN to feel drag while spinning the pushrod, you are at zero lash. Once zero lash is reached, stop and add your preload. DO NOT go back and try to feel the adjustment. The lifter will immediately begin to bleed down a little. Tension on the pushrod will relax and this will make it seem like your adjustment did not work. If you want to recheck zero lash, you must loosen the rocker arm nut and tighten it down again while spinning the pushrod as before. At that point you want to set the preload and LEAVE IT ALONE.

For reference:

3/8" stud: ?flat = .003472"

7/16" stud: ?flat = .00416"

Rotating the nut 1/6 of a turn (until the next flat side is in the same position as the previous flat side) is a "flat".

Consequences of improper adjustment:

Too tight - the valves will not completely close and you will lose compression. The engine will run rough, if it will run at all.

Too loose - the rocker arms will make noise from the slack and pushrods could be dislodged. Possible damage could occur from either extreme.

Some like to adjust the rockers while the car is idling. If you wish to do this, loosen one rocker at a time until you can hear it click. Tighten the nut, but don't exert downward pressure on the rocker arm with your socket. At the point when audible clicking is gone, tighten the nut another 1/4 turn for your preload (Comp R lifters, less as noted above).

If you have never had the crank hub off (or know for sure that it's orientation is correct), you can use the arrow that is on the balancer to tell you where you are. You don't have to spin the crank every 90?with this method.

When at #1 TDC you can adjust the following valves:

Intake: 1, 2, 5, 7

Exhaust: 1, 3, 4, 8

Rotate the crank one revolution until the pointer is again at 12 o'clock. This will let you adjust the remainder of the valves. If you did #1 the previous time, you should be now at #6 TDC.

When at #6 TDC you can adjust the following valves:

Intake: 3, 4, 6, 8

Exhaust: 2, 5, 6, 7

If you want to set the lash by bringing each cylinder to TDC, watch the valves and the pointer on the balancer and follow the Firing order:

1-8-4-3

6-5-7-2

Adjust both intake and exhaust of the cylinder that is at TDC. You will have to make 2 revolutions of the crank, stopping at 1/4 (90? turn intervals for each cylinder.

Another cylinder by cylinder method that does not require looking at the balancer position, follows:

(A remote starter switch is quite helpful)

Here is something additional for those that use "poly locks" (typically used with roller rockers).

Since the poly lock is not a prevailing torque fastener like the nut used with the stock rocker and ball arrangement, it spins freely on the rocker stud. This gives you an advantage to finding zero lash. With the allen lock backed off, spin down the nut until it just stops. This is very close, if not right on zero lash in most cases. Check your pushrod for proper movement and play with it to get a feeling just how snug or loose the nut should be to obtain zero lash. Once you do that, you can just use the nut to reach zero lash and not have to worry about messing with the troublesome pushrod. This will speed up your valve adjustment.

Another aide is to make a mark on the top of the nut so that you can easily see how far you have turned the nut. I always found it a little difficult to obtain the exact amount of rotation on the nuts under the cowl, because of there being less room to swing a ratchet or other tool handle. I used a little dab of white paint on the top and was easily able to tell when I made a half turn or whatever was needed. Now, I can just use a wrench to tighten the nuts, then throw the allen wrench on it and snug the set screw down (while holding the nut).

Some like to run the allen set screw down and then tighten it and the nut together. If you overdo it this way, you may break the nut. I always have good luck with setting the nut and then the set screw. With all the variables in making adjustments to hydraulic lifters like the number of turns for preload, methods of finding zero lash and trying to see what you are doing under the cowl, slight errors are common. Just try to be as consistent as possible and use the method that works best for you.

edited 1/6/2008

![]()

![]()

The opti has two functions in the spark process. The first thing that happens is as the cam turns, the optical section of the optispark picks up the signals by the rotation of the shutter wheel. The pulses are sent to the PCM via the optispark electrical harness. The PCM processes the signals along with other sensor input and determines the proper time for the coil to fire. The PCM sends a signal to the Ignition Control Module (ICM) and it, in turn, causes the coil to fire. The spark from the coil travels through the coil wire back to the secondary ignition section of the optispark (cap and rotor), to be distributed to the proper cylinder.

If the opti is never sending the signal to the PCM, the PCM will never send a signal to fire the coil.

Here is some testing you can do. Refer to this diagram.

Disconnect the ICM connector. Leave coil connected.

Turn key to ON.

Check for dc voltage with a digital meter at harness terminal "A" to ground and and also "D" to ground. Note: Use a high impedance meter (at least 10 megohm) when dealing with the PCM.

Result should be 10v dc or more on both terminals. If you get no voltage, use the diagram and chase back toward the coil and the ignition fuse. Power for the ICM comes from the ignition fuse and through the coil, so any of that could be bad.

If you have good voltage, switch the meter to ac scale and connect test leads to terminal "B" and to ground. Observe meter while cranking the engine. You should see between 1 and 4 volts ac (those are the pulses that trigger the coil to fire).

![]()

Pellet Code

Key Resistance in Ohms

Nominal

Low

High

1

402

386

438

2

523

502

564

3

681

654

728

4

887

852

942

5

1130

1085

1195

6

1470

1411

1549

7

1870

1795

1965

8

2370

2275

2485

9

3010

2890

3150

10

3740

3590

3910

11

4750

4560

4960

12

6040

5798

6302

13

7500

7200

7820

14

9530

9149

9931

15

11800

11328

12292

Use a multimeter to check the resistance of the pellet in the key and compare to the table above. Touch the meter leads to each side of the pellet on the metal bar. The nominal reading is the ideal reading. It most likely will be in the range delimited by "low" and "high". There are 15 different key pellets used. Use this information when you need to get a new key made or for finding a resistor if you wish to bypass the system.

edited 1/24/2005

![]()

![]()

![]()

Some people have reported ignition problems that seem to be heat related. One item that can be relieved of some heat stress is the Ignition Control Module (ICM). Merely spacing the coil and ICM bracket away from the cylinder head has solved miss problems in some cases. Any time you can reduce the amount of heat in an electronic component, it will normally prolong it's life and allow for more stable operation.

Getting to the coil and coil replacement is covered elsewhere in my Tech Pages, so I am not going to step through that procedure.

On my 1995 Z, I used a very simple approach to creating some space between the coil bracket and the head. I used some common 3/8" flat washers that I already had laying around. After removing the coil and studs, I put 2 washers between the "stud nut" and the cylinder head on the inboard stud. There is also a bracket for the EVAP hose that goes on this stud to take up some room. I used 3 washers on the outboard stud. With the thickness of the washers I had, this made the distance on each stud approximately the same (approximately 3/16").

The washers are used, because without the coil bracket sandwiched on the stud, the threads would bottom out in the head. This just gives a little extra space, which is not a problem.

Once the washers are in place and the studs screwed back in, you can mount the coil on the outside of the stud nut, instead of the inside where it was before. Torque value for both the stud to head and the nut is 18 lb. ft.

The total gap came out to about 1/2". Note that one of the studs has more threads on the outside portion of the stud nut. This is the stud that goes in the outboard head hole and is longer to accomodate the ground straps attached to it.

Another note: 1993 owners may have a bolt instead of a stud on the inboard side and others may have identical studs on both sides. It really does not matter. The intent is to create an air space between the head and the coil bracket. A little ingenuity and a couple of additional fasteners may be needed.

Tighten up the fasteners and reconnect electrical harnesses and you are done. I don't have any dyno runs or temperature comparisons for before and after, but for next to nothing in cost, this mod can't hurt.

I am not the first one to do this and it could be done using other methods and materials (perhaps, even more effectively). This just happens to be the way I did mine.

Update: At least one person monitored the temperature of the ICM and the head after the mod. With the engine running, the ICM stayed cooler, but when the engine was turned off, the ICM did not dissipate heat as fast as the head did. I did not get any info on how long the ICM stayed hotter. I am just providing that for your information and you can draw your own conclusions.

5/10/2003

![]()

If you have issues you need to track further, a leakdown test will be able to tell you whether rings, valves or head gasket might be leaking.

edited 5/10/2003

![]()

A fuel pressure test gauge can be bought at your local auto supply for ~$35. Attach it to the schrader valve that is on the fuel rail. Schrader valve location on 1994-1997

edited 2/05/2007

![]()

Most people notice that the fuel gauge does not read in a linear fashion. It will stay on the full side for a long time and then once it starts moving, it will drop rapidly. This is due to the shape of the tank and the placement of the float assembly/gauge sender unit. The tank has a bit of a wedge shape to it, that causes there to be more volume in the upper part of the tank than in the lower. The float only reacts to an up and down level and does not compensate for the tank shape.

Locate the pump electrical connector on the rear of the floor pan under the car (above the LH axle tube). It has purple, gray and black wires going toward the fuel tank. Unplug the connector. With a meter set to ohms, read resistance between the black and purple wires going to the tank.

The readings should correspond to your gauge. If the reading(s) seem accurate to what you have in the tank, the sender is ok. If they don't, the sender or wiring from that connector to the sender has a problem.

edited 2/22/2005

![]()

Note that the 1993 IAC has a square electrical connector and the valve screws into the throttle body, instead of being held on by screws like those of later years.

edited 4/15/04

![]()

This is a common fix for when the air no longer blows out the vents. When there is not enough vacuum to operate the actuators, they will only direct air to the floor and defrost ducts by default. Diagram of HVAC system.

edited 4/13/2004

![]()

![]()

Late model 1998 and up axles used a smaller hub center on the rear axles. Therefore the wheels were made with a smaller hub opening on the back. When you try to swap these wheels onto an earlier model 4th gen, the center of the wheel won't fit over the rear axle hub. The wheel has to be relieved a small amount to allow it to slip on. You can dry fit the wheel to "mark" where the interference is, then you will be able to see the area that needs attention. Use a Dremel, sandpaper or even a half-round file to take of the little bit that is required. It does not have to be perfect, as the wheels are centered by the conical lug nuts, not the hub and that part of the wheel is never visible. Just relieve it enough to get the wheel on/off easily. If you ever intend to rotate your tires, you will want to do this to all four wheels (The fronts will fit without any modification. There are no clearance issues with them). Don't ever try to force the wheel on with the lug nuts. You can strip lug studs and/or get the wheel stuck.

![]()

and is it OBD-I or OBD-II?

1993-1995 LT1 f-body cars have one cat, with the exception being California Emissions (RPO NB6) A4 cars having two. All 1995 M6 cars have one cat.

edited 10/10/2008

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

2000

04-Dec 1998 Chrysler .09/1.1/.17/.--/.-- Qe Passed 4,548

WCRXV0195V20

08-Feb 1997 General Motors .18/2.53/.26/.23/.36 T Passed 29,630

VGM5.7HPG1EK

18-Jan 1997 Toyota .14/1.86/.19/.14/.38 Re Passed 15,365

VTY3.42JG2GK

04-Jan 1997 Chrysler .18/3.36/.66/.34/.54 Pb Passed 8,443

VCR14828G1EK

1999

14-Dec 1997 General Motors 2.2L .06/1.24/.32/.16/.47 Qe Passed 26,999

VGM2.2V8G2EK

07-Dec 1997 Ford 5.0L-T .15/2.21/.12/.16/.38 Te Passed 21,625

VFM5.028GFEK

16-Nov 1997 Toyota 2.2L .06/1.05/.14/.04/.22 Vb Passed 44,619

VTY2.2VJG3GK

09-Nov 1997 Volkswagen 2.8L .14/1.15/.20/.04/.27 P Passed 3,442

VVW2.8V8GFGM

02-Nov 1997 Volvo 2.9L .12/1.40/.05/.01/.47 P Passed 2,950

VVV2.9VJGFEL

26-Oct 1997 General Motors 4.3L-T .14/1.68/.27/.12/.-- Te Passed 9,957

VGM4.31PG1EK

19-Oct 1997 Ford 3.0L .05/1.23/.06/.07/.41 Ve Passed 40,567

VFM3.0V8G3EK

12-Oct 1997 Rover 4.0L .26/2.28/.38/.49/.87 Te Failed - Recalled 2,273

VLR4.058GFFK Evaporative System Defects

05-Oct 1997 General Motors 5.0L-T .21/2.1/.26/.21/.2 T Passed 4,622

VGM5.0HPG1EK

28-Sep 1997 Mitsubishi 2.5L .14/1.0/.23/.03/.-- Pe Passed 3,859

VDS2.5VJGKEK

21-Sep 1997 Mercedes 2.3L .06/0.6/.07/.02/.4 Q Passed 5,593

VMB2.3VJGKEK

14-Sep 1997 Chrysler 4.0L-T .06/0.8/.22/.03/.-- Re Passed 13,806

VCR24228G2JK

08-Sep 1997 General Motors 5.7L .17/3.0/.34/.35/.2 P Passed 4,136

VGM5.7V8G1EK

17-Aug 1997 Hyundai 1.8L .20/0.74/.29/.07/.-- Pe Passed 3,479

VHY1.8VJG1EK

10-Aug 1997 Kia 2.0L-T .14/1.50/.15/.08/.-- Se Passed 4,059

VKM2.01JG1EK

03-Aug 1997 Nissan 4.1L .12/1.3/.19/.07/.18 P Passed 4,334

VNS4.1VJG1EK

28-Jul 1997 General Motors 4.3L-T .11/1.7/.28/.20/.-- Rb Passed 14,611

VGM4.32PG2EK

20-Jul 1997 Chrysler 5.9L-T .20/3.40/.35/.13/.21 Tb Passed 12,801

VCR36028G1EK

13-Jul 1997 Honda 1.6L .05/1.78/.09/.04/.24 Vb Passed 41,960

VHN1.6VJG3EK

22-Jun 1997 Ford 5.4L-T .13/1.01/.17/.10/.-- Ub Passed 20,488

VFM5.4J8G1FK

15-Jun 1997 BMW 1.9L .09/0.93/.28/.23/.-- Qe Passed 5,191

VBM1.9VJGKFK

08-Jun 1997 Mazda 1.8L .19/1.41/.22/.04/.22 P Passed 2,822

TTK1.8VJGKEK

In-Use Compliance testing was limited in 2000 due to significant programmatic changes

Page 1

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

25-May 1996 General Motors 4.6L .24/1.89/.27/.08/.31 P Passed 19,651

TGM4.6VJGFEL

18-May 1996 Nissan 3.0L .09/0.92/.31/.13/.66 P Passed 24,399

TNS3.0VJGFEK

11-May 1996 DSM 2.4L .10/1.85/.10/.05/.-- Q Passed 14,606

TDS2.4VJG2EL

04-May 1996 Chrysler 239 T .18/2.52/.23/.12/.62 T Passed 7,316

TCR23928G1EK

27-Apr 1996 Volvo 2.4L .07/0.50/.11/.04/.-- Q Passed 5,364

TVV2.4VJGKEK

13-Apr 1996 Suzuki 1.3L .10/1.68/.09/.01/.-- P Passed 5,686

TSK1.3V5GDFB

06-Apr 1996 Subaru 2.2L .10/1.50/.13/.10/.-- Q Passed 3,362

TFJ2.2VJG2EK

30-Mar 1996 General Motors 2.2L-T .09/1.92/.18/.10/.39 S Passed 15,173

TGM2.218GFEK

16-Mar 1996 Hyundai 1.5L .06/0.87/.06/.07/.23 Q Passed 5,202

THY1.5VJG2FK

09-Mar 1996 Ford 3.0L-T .17/1.58/.37/.26/1.30 S Passed 4,449

TFM3.018G1EK

02-Mar 1996 General Motors 7.4L-T .16/1.61/.44/.19/.22 U Passed 7,637

TGM7.4J8G1EK

23-Feb 1996 Toyota 4.5L-T .24/2.29/.33/.09/.38 T Passed 3,334

TTY4.55JGFEK

09-Feb 1996 Honda 2.7L .16/1.10/.23/.05/.15 P Passed 4,880

THN2.7VJG1EK

02-Feb 1996 Kia 1.8L .13/1.34/.18/.02/.-- P Failed - Recalled 5,095

TKM1.8VJG1EK Evaporative System Defects

26-Jan 1996 General Motors 2.2L .08/1.73/.08/.08/.40 Q Passed 30,217

TGM2.2V8G2EK

19-Jan 1996 Chrysler 318 T .22/3.21/.27/.07/.21 T Passed 13,330

TCR31828G1EL

12-Jan 1996 General Motors 4.3L-T .12/1.69/.29/.11/.40 T Passed 6,606

TGM4.35PGFEK

05-Jan 1996 BMW 2.8L .10/1.73/.27/.10/.-- Q Passed 8,224

TBM2.8VJGKEK

1998

08-Dec 1996 Ford 3.0L .15/1.59/.16/.05/.-- P Passed 13,782

TFM3.0VJG1EK

01-Dec 1996 General Motors 1.9L .10/0.80/.19/.05/.42 Q Passed 11,837

TGM1.9V8G2EK

10-Nov 1996 Mazda 2.0L .10/1.01/.21/.09/.50 Q Failed - Recalled 5,001

TTK2.0VJG2EK Evaporative System Defects

03-Nov 1996 Nissan 2.4L .07/1.16/.22/.22/.28 Q Passed 20,218

TNS2.4VJG2EK

27-Oct 1996 Chrysler 201 .14/1.35/.20/.09/.30 Q Marginal Fail-No Recall 3,017

TCR201V8G2EK

15-Sep 1996 Ford 4.0L-T .07/0.87/.40/.39/.33 R Passed 40,264

TFM4.028G2FK

01-Sep 1996 General Motors 5.7L .16/3.16/.24/.15/.-- P Passed 8,956

TGM5.7V8GFEK

18-Aug 1996 Ford 4.6L .10/1.60/.21/.04/.-- P Passed 8,076

TFM4.6V8G1FK

11-Aug 1996 Toyota 2.7L-T .10/2.31/.14/.08/.26 S Failed - Recall Pending 5,799

TTY2.71HGKEK OBD2 System Defects

04-Aug 1996 General Motors 4.3L-T .13/1.69/.37/.12/2.27 Ti Passed 19,479

TGM4.32PGKEK

Page 2

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

21-Jul 1996 Isuzu 3.2L-T .08/0.92/.32/.04/1.46 R Passed 8,691

TSZ3.22JGKGK

14-Jul 1996 General Motors 4.3L-T .12/1.66/.30/.13/.41 S Passed 6,224

TGM4.31PGFEK

07-Jul 1996 General Motors 4.3L-T .13/1.92/.38/.15/.-- T Passed 20,604

TGM4.32PGKEL

23-Jun 1996 Honda 1.6L .03/1.18/.10/.03/.-- V Passed 31,737

THN1.6VJG3EK

16-Jun 1996 General Motors 3.1L .15/1.51/.23/.14/.-- P Passed 67,216

TGM3.1V8GFEK

09-Jun 1996 Mazda 1.5L .06/0.98/.08/.04/.-- Q Passed 6,138

TTK1.5VJG2EK

02-Jun 1995 General Motors 2.2L-T .14/2.58/.40/.20/.-- S Passed 13,583

S3G2.217G1EA

27-May 1995 Jaguar 4.0L .xx/x.xx/.xx/.xx/.xx P No Decision 5,083

SJC4.0VJGFEK Insufficient Sample

19-May 1995 Nissan 2.4L-T .10/1.27/.23/.12/.-- S Passed 15,802

SNS2.41JGFEA

12-May 1995 Mercedes Benz 3.6L .08/0.95/.14/.02/.31 P Passed 10,142

SMB3.6VJGFEK

05-May 1995 General Motors 5.7L-T .28/5.85/.75/.33/.53 Ui Passed 22,042

S3G5.7J5G1EA

28-Apr 1995 Diamond Star 2.4L .08/1.47/.16/.11/.-- Q Passed 7,675

SDS2.4VJG2EA

21-Apr 1994 General Motors 3.1L .13/1.53/.32/.15/.-- P Passed 65,929

R1G3.1V8GFEA

14-Apr 1995 Ford 1.9L .08/1.69/.26/.10/1.01 Q Passed 51,312

SFM1.9V8G2EA

07-Apr 1995 General Motors 4.3L-T .21/2.94/.65/.64/.-- T Passed 7,690

S3G4.329GFGJ

24-Mar 1995 Volvo 2.4L .13/1.94/.21/.04/.59 P Passed 5,079

SVV2.4VJGFEK

17-Mar 1995 Volkswagen 2.0L .16/2.3/.12/.03/.7 P Passed 13,834

SVW2.0V8GFEA

10-Mar 1995 Chrysler 4.0L-T .15/2.09/.36/.17/.-- T Passed 18,985

SCR24228G1EA

03-Mar 1995 General Motors 5.7L-T .31/4.98/.86/.37/.37 E Passed 11,363

S3G5.7H5G0EA

24-Feb 1995 Isuzu 3.2L-T .30/3.1/.27/.--/.3 T Passed 14,027

SSZ3.22HGKHA

18-Feb 1995 Ford 5.8L-T .08/0.94/.31/.15/.37 T Passed 9,995

SFM5.8H8G1EA

10-Feb 1995 Hyundai 1.5L .16/1.1/.17/.04/.7 P Passed 13,834

SHY1.5VJG1EB

03-Feb 1995 General Motors 1.9L .14/1.61/.26/.15/.77 Q Passed 14,380

S4G1.9V7G2EA

27-Jan 1995 General Motors 4.6L .18/2.11/.24/.16/.42 P Passed 14,632

S1G4.6VJGFEA

21-Jan 1995 Mitsubishi 3.0L-T .09/1.0/.08/.02/.-- R Passed 4,508

SMT3.02JG2EA

13-Jan 1995 General Motors 5.7L-T .26/4.77/.69/.34/.51 Ti Passed 28,835

S3G5.785GBEB

06-Jan 1995 BMW 4.0L .14/0.9/.36/.25/.3 P Passed 7,256

SBM4.0VJGFEA

1997

09-Dec 1995 Suzuki 1.3L .11/2.00/.11/.01/.3 P Passed 5,701

SSK1.3V5GDFA

Page 3

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

02-Dec 1995 General Motors 4.3L-T .40/4.77/.88/.60/.4 E Passed 4,371

S3G4.3H5G0EA

18-Nov 1995 Chrysler 5.9L-T .28/5.40/.58/.20/.8 Ti Passed 6,819

SCR360H8G1FA

11-Nov 1995 Chrysler 2.0L .19/2.70/.27/.08/.3 P Passed 10,788

SCR2.0VJGFEK

04-Nov 1995 Nissan 3.0L .11/2.30/.21/.22/.-- P Passed 38,803

SNS3.0VJG1EK

28-Oct 1995 Ford 3.8L .08/1.20/.19/.07/1.5 P Passed 3,501

SFM3.828G1EK

21-Oct 1995 General Motors 4.3L-T .xx/x.xx/.xx/.xx/.xx T No Decision 7,490

S3G4.329GFEA Insufficient Sample

14-Oct 1995 Kawasaki 500cc MC .71/7.7/.47/.--/.-- Passed 1,400

SKA.50PAGARA Std. .80/12.0 g/km

07-Oct 1995 Honda 1.1MC .90/9.2/.44/.--/.-- Passed 1,086

SHN1.1PAGARD Std. .90/12.0 g/km

30-Sep 1995 Honda 2.2L .10/1.6/.15/.01/.1 P Passed 5,458

SHN2.2VJGKEA

23-Sep 1995 Ford 4.0L-T .10/1.5/.36/35/.-- T Passed 16,532

SFM4.028G1EK

16-Sep 1995 General Motors 4.3L-T .53/7.0/.55/.42/.6 T Passed - CPI Fuel Injector 33,725

S3G4.329GFHB Defect - Extended Warranty

09-Sep 1995 Toyota 2.2L .08/1.10/.22/.05/.3 Q Passed 34,658

STY2.2VJG2GA

22-Jul 1995 Isuzu 3.2L-T .30/3.10/.27/.--/.30 T Passed 14,027

SSZ3.22HGKHA

15-Jul 1995 Mazda 2.0L .11/1.10/.22/.15/.40 Q Passed 10,146

STK2.0VJG2EA

08-Jul 1995 General Motors 3.1L .15/2.10/.35/.17/.20 P Passed 82,333

S1G3.1V8GFEA

08-Jul 1995 General Motors 4.3L-T .19/2.70/.43/.31/.20 S Marginal Failure - No Recall 4,375

S3G4.315GEEA

17-Jun 1994 Ford 3.8L .17/2.10/.12/.09/.10 P Passed 8,190

RFM3.8V8G1EK

03-Jun 1994 General Motors 2.2L-T .27/3.70/.36/.21/.10 N Passed 7,516

R3G2.277GAEA

27-May 1994 Ford 4.6L .15/1.80/.34/.12/.50 P Passed 18,843

RFM4.6V8G1EK

20-May 1994 Volkswagen 2.0L .20/2.80/.19/.06/.50 P Passed 6,090

RVW2.0V8GEFA

13-May 1994 Hyundai 1.8L .30/2.30/.15/.02/.60 P Passed 2,391

RHY1.8VJG1FB

06-May 1994 General Motors 4.3L-T .32/4.90/.40/.11/.70 E Passed 5,383

R3G4.375GAEA

22-Apr 1994 BMW 4.0L .23/1.5/.29/.12/.3 K Passed 4,491

RBM4.0VJGAEA

15-Apr 1994 Toyota 4.5L-T .23/4.2/.85/.90/.3 E Passed 3,652

RTY4.58JGAEA

08-Apr 1994 General Motors 3.1L .18/2.0/.64/.60/.5 P Failed 65,929

R1G3.1V8GFEA "A" Body Vehicles Recalled

21-Mar 1994 Ford 4.0L-T .22/3.1/.45/.25/1.1 O Passed 13,957

RFM4.028G1EA

12-Mar 1994 Suzuki 1.6L-T .14/1.7/.20/.21/.2 S Passed 5,272

RSK1.61JGDHA

04-Mar 1994 General Motors 4.3L-T .35/6.2/.76/.53/.4 E Passed 8,113

R3G4.385GAEB

25-Feb 1994 Honda 1.8L .18/3.1/.18/.08/.2 P Passed 15,942

RHN1.8VJGFEA

Page 4

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

18-Feb 1994 Nissan 2.4L .15/3.1/.24/.08/.5 P Passed 23,788

RNS2.4VJGDEA

04-Feb 1994 General Motors 3.8L-T .12/1.7/.36/.26/.4 R Passed 4,421

R3G3.828G2EA

22-Jan 1994 Mercedes 3.2L .11/1.8/.18/.11/.2 P Passed 6,476

RMB3.2VJGFFA

08-Jan 1994 General Motors 5.7L-T .40/6.8/.84/.54/.3 E Passed 43,468

R3G5.785GAEB

07-Jan 1994 Jaguar 4.0L .29/4.0/.16/.15/.5 P Passed - ECS Defect 2,863

RJC4.0VJGFEK Recalled

1996

10-Dec 1994 Mazda 3.0L-T .20/3.2/.29/.11/.3 O Passed 7,372

RTK3.02HG1EA

03-Dec 1994 Isuzu 3.2L-T .26/2.5/.41/.23/.6 O Passed 9,921

RSZ3.22HGDEA

19-Nov 1994 General Motors 4.3L-T .55/8.40/.46/.39/.30 O Failed - Recall Pending 9,085

R3G4.329GFEA

29-Oct 1994 Chrysler 2.5L .15/3.0/.54/.16/.1 Pi Passed 14,973

RCR2.5V5GEEA

22-Oct 1994 Ford 3.8L .10/1.9/.43/.45/.2 Pi Passed 24,442

RFM3.8V8G1GA

15-Oct 1994 General Motors 3.1L-T .20/5.1/.56/.25/.6 Oi Passed 3,645

R3G3.125GFEA

24-Sep 1994 Mitsubishi 1.5L .15/2.0/.16/.03/.3 P Passed 4,446

RMT1.5VJGFEA

17-Sep 1994 Hyundai 1.5L .14/1.5/.25/.09/.5 P Passed 6,028

RHY1.5V8G1EB

10-Sep 1994 Toyota 2.2L .07/1.1/.29/.11/.10 Q Passed 32,564

RTY2.2VJG2GA

04-Sep 1994 General Motors 5.7L .25/3.8/.44/.53/.4 Ki Passed 5,490

R1G5.7V8GOEB

19-Nov 1994 General Motors 4.3L-T .55/8.4/.46/.39/.3 O Failed - Recall Pending 9,085

R3G4.329GFEA

20-Aug 1993 Harley Davidson 1.3MC .72/10.1/.84/.--/.-- Passed 4,914

EV1340 Std. 1.00/12.0 g/km

13-Aug 1994 General Motors 4.3L-T .49/6.5/.55/.34/.3 O Failed - Recall Pending 13,639

R3G4.389GAEA

06-Aug 1994 General Motors 1.9L .17/2.8/.23/.08/.3 P Passed 10,757

R4G1.9V5GEEA

30-Jul 1994 DSM 2.4L .15/1.9/.34/.12/.3 P Passed 4,521

RDS2.4VJGFEA

23-Jul 1994 Kia 1.6L .19/2.9/.17/.09/.30 P Passed 6,718

RKM1.6VJGEEA

16-Jul 1994 Chrysler 4.0L-T .16/1.7/.45/.22/.80 P/Oi Passed 6,769

RCR24218G1EA

09-Jul 1994 General Motors 4.3L-T .24/4.7/.56/.24/.2 Oi Passed 14,980

R3G4.325G1EA

25-Jun 1994 Nissan 1.6L .18/2.3/.31/.12/.60 P Passed 42,255

RNS1.6VJG1EA

04-Jun 1993 General Motors 4.3L-T .60/9.7/.47/.37/.70 O Failed - Recall Pending 9,750

P3G4.3XBXE33

21-May 1993 Mazda 2.5L .24/4.6/.20/.03/.5 K Passed 4,418

PTK2.5V5FCL4

14-May 1993 BMW 1.8L .14/1.4/.21/.19/.4 K Passed 4,069

PBM1.8V5F421

07-May 1993 General Motors 3.1L .16/2.5/.34/.28/.2 P Passed 9,750

P1G3.1W8MCF5

Page 5

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

30-Apr 1993 Isuzu 1.6L .16/3.1/.13/.10/.40 P Passed 3,108

PSZ1.6V5FHE1

23-Apr 1993 Suzuki 750cc MC 1.16/9.45/.--/--/-- Passed 1,440

NSK074844S2 Std. 1.6/12.0 g/km

16-Apr 1993 Ford 4.0L-T .10/1.9/.20/.06/1.6 O Passed 49,027

PFM4.0T5FCC6

09-Apr 1993 Ford 1.9L .10/2.5/.30/.09/1.0 Q Passed 49,276

PFM1.9V5FCC2

02-Apr 1993 General Motors 2.0L .13/3.4/.18/.08/.4 P Passed 10,096

P1G2.0W8JF15

26-Mar 1993 Honda 2.2L .09/2.1/.17/.05/.4 P Passed 26,621

PHN2.2V5FPZ0

19-Mar 1992 Kawasaki 500cc MC .45/8.8/.--/.--/.-- Passed 1,600

NKA049842A7 Std. 0.80/12.0 g/km

12-Mar 1993 Volvo 2.3L .11/2.9/.10/.07/.4 P Passed 3,920

PVV2.3V5FP88

05-Mar 1993 General Motors 1.9L .25/4.3/.18/.07/1.1 K Passed 17,503

P4G1.9W8JPD9

27-Feb 1993 Mitsubishi 1.5L .17/2.5/.21/.07/.3 P Passed 3,508

PMT1.5V5FC45

20-Feb 1993 Hyundai 1.8L .32/4.0/.35/.09/.5 K Passed 1,728

PHY1.8V5FC49

13-Feb 1993 General Motors 4.9L .20/4.6/.56/.45/.3 Ki Marginal Fail - No Recall 16,684

P1G4.9W8XTAX

06-Feb 1993 General Motors 1.9L .16/3.1/.30/.07/.4 P Passed 9,435

P4G1.9W5J817

30-Jan 1993 Mercedes 5.0L .18/2.8/.14/.06/.3 P Passed 5,218

PMB5.0V5FA12

16-Jan 1993 Ford 4.6L .17/4.7/.41/.36/.2 Ki Passed 22,280

PFM4.6V5FDCX

09-Jan 1993 Ford 2.3L .14/4.2/.30/.24/1.1 N Passed 12,489

PFM2.3T5FMLX

03-Jan 1993 General Motors 5.7L-T .61/7.5/1.11/.63/.5 E Failed - Recall Pending 38,002

P3G5.7T5TYA8

1995

12-Dec 1993 Suzuki 1.0L .13/2.2/.25/.07/.4 K Passed 7,959

PSK1.0V5FFC6

05-Dec 1993 General Motors 4.3L-T .20/3.1/.97/.75/.6 O Passed 16,444

P3G4.3X5XG38

28-Nov 1993 Chrysler 215 .31/3.1/.46/.15/.5 Ki Passed 5,219

PCR215V5FPG2

14-Nov 1993 Nissan 2.4L .15/2.2/.29/.19/.7 P Passed 14,554

PNS2.4V5FBC5

07-Nov 1993 General Motors 4.3L-T .97/15.6/.90/.56/.3 E Failed - Recalled 5,280

P3G4.3TBTAB6

31-Oct 1993 General Motors 2.3L .06/0.9/.29/.13/.5 Q Passed 10,746

P1G2.3W8MAY7

24-Oct 1993 Chrysler 153 .10/2.7/.28/.10/.3 P Passed 9,773

PCR153V5FEN4

17-Oct 1993 Range Rover 4.2L .17/2.4/.63/1.19/1.3 E Passed 1,691

PLR4.2T5FSS8

10-Oct 1993 Mazda 2.0L .14/1.6/.25/.06/.6 P Passed 4,704

PTK2.0V5FWL2

03-Oct 1993 General Motors 4.3L-T .27/3.4/.33/.27/.5 N Passed 4,167

P3G4.3T5XEB5

26-Sep 1993 Ford 3.8L .10/1.4/.27/.21/.2 P Passed 30,175

PFM3.8V5FAC8

Page 6

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

19-Sep 1993 Toyota 1.8L .16/3.1/.37/.17/.1 P Passed 12,399

PTY1.8V5FCD3

12-Sep 1993 Volkswagen 2.0L .17/2.9/.26/.15/.8 P Passed 5,857

PVW2.0V5FWA1

06-Sep 1993 General Motors 4.3L-T .57/8.1/.94/.30/.4 E Failed - Recall Pending 11,431

P3G4.3T5TAA6

22-Aug 1993 Nissan 1.6L .15/2.1/.32/.14/.7 P Passed 24,363

PNS1.6V5FAA5

15-Aug 1993 Ford 4.9L-T .35/3.1/.60/.79/.4 E Passed 5,543

PFM4.9T5HGL8.2M

08-Aug 1993 Ford 2.0L .15/1.7/.23/.07/.3 P Passed 5,344

PFM2.0V5FXC8

01-Aug 1993 Chrysler 4.0L-T .23/2.6/.26/.20/.4 O/N Passed 15,743

PCR242T5FKY8.2M

25-Jul 1993 Chrysler 3.0L-T .17/1.4/.34/.20/.1 O Passed 17,047

PCR181T5FJV6.2

18-Jul 1992 Honda 600cc MC .68/9.1/.--/.--/.-- Passed 4,445

NHN060044F4 Std. 1.1/12.0 g/km

18-Jul 1992 Isuzu 3.1L-T .46/10.1/.58/.--/.-- E Failed - Recall Pending 6,789

NSZ3.1T5FKB4

11-Jul 1993 Honda 1.5L .13/2.0/.26/.14/.2 K/P Passed 33,166

PHN1.5V5FDC9

27-Jun 1993 Isuzu 3.2L-T .29/4.0/.40/.69/.4 O Passed 4,380

PSZ3.2T5FHF6

20-Jun 1993 BMW 2.5L .15/1.9/.17/.12/.5 K Passed 13,508

PBM2.5V5FT1X

13-Jun 1993 Hyundai 1.5L .16/1.6/.17/.03/.5 P Passed 5,619

PHY1.5V5FCAX

23-May 1992 Toyota 3.0L .14/1.3/.32/.13/.5 K Passed 14,856

NTY3.0V5FCV3

16-May 1992 Suzuki 1.6L-T .13/4.4/.16/.02/.4 M Passed 3,341

NSK1.6T5FCC8

15-May 1992 General Motors 4.3L-T .27/3.6/.76/.--/.-- N Failed - Recall Pending 12,400

N3G4.3TBXEB2

09-May 1992 Mazda 1.6L .16/2.3/.24/.19/.4 K Passed 5,984

NTK1.6V5FCSX

02-May 1992 Ford 4.0L-T .12/2.6/.34/.13/1.8 E Passed 50,492

NFM4.0T5FAM1

18-Apr 1992 Volvo 2.3L .15/2.00/.17/.08/.5 F Passed 6,687

NVV2.3V5FE82

11-Apr 1992 General Motors 5.7L .24/3.20/.33/.11/1.7 K Passed 6,439

N1G5.7V5XEA2

04-Apr 1992 Nissan 2.4L-T .34/3.40/.21/.08/.70 N Passed 12,275

NNS2.4T5FCC6

21-Mar 1992 Honda 2.5L .17/2.20/.16/.04/.30 K Passed 5,002

NHN2.5V5FHC1

14-Mar 1992 General Motors 4.3L-T .24/3.00/.69/.--/.-- E Passed 3,190

N3G4.3TBXEB2 (>3751lbs)

07-Mar 1992 Chrysler 3.9L-T .24/2.50/.49/.36/.50 E Passed 4,989

NCR3.9T5FGX0

21-Feb 1992 Hyundai 1.6L .41/3.40/.30/.09/.60 F Passed 3,517

NHY1.6V5FCA3

14-Feb 1992 Toyota 2.4L-T .10/1.20/.19/.10/.30 N Passed 11,267

NNT2.4T5FCC7

07-Feb 1992 Suzuki 1.0L .25/3.10/.20/.07/.50 F Passed 14,976

NSK1.0V5FFC4

17-Jan 1992 General Motors 5.7L-T .65/9.70/1.25/.--/.-- Li Marginal Failure 3,677

N3G5.7T5TYA6 (>3751lbs) No Recall

Page 7

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

17-Jan 1992 General Motors 5.7L-T .66/9.40/1.13/.60/.40 E Failed - Recalled 26,534

N3G5.7T5TYA6

10-Jan 1992 BMW 2.5L .18/1.90/.26/.18/.30 K Passed 6,314

NBM2.5V5F500

04-Jan 1992 General Motors 1.9L .44/5.10/.36/.27/.60 K Marginal Failure 10,297

N4G1.9V8JPD2 No Recall

1994

07-Dec 1992 Mitsubishi .27/2.7/.29/.07/.70 K Passed 2,954

NMT3.0V5FC29

06-Dec 1992 Toyota 2.2L .13/1.9/.25/.06/.10 O Passed 22,503

NTY2.2V5FCE7

15-Nov 1992 Isuzu 1.6L .24/4.2/.31/.05/.60 F Passed 5,476

NSZ1.6V5FCE0

08-Nov 1992 Chrysler 2.5L-T .20/5.70/.17/.02/.60 N Passed 4,081

NCR150T5FDV5

07-Nov 1992 Mitsubishi 2.4L-T .19/3.2/.20/.22/.50 N Passed 4,228

NMT2.4T5FC13

25-Oct 1992 Mitsubishi 1.8L .19/1.7/.26/.20/.50 K Passed 3,696

NDS1.8V5FC19

18-Oct 1992 General Motors 2.2L .20/3.4/.24/.07/.50 K Passed 5,756

N1G2.2W8JFGX

11-Oct 1992 General Motors 4.3L-T .65/7.2/1.25/.72/.40 E Failed - Recalled 26,677

N3G4.3TBTAA3

04-Oct 1992 Mazda 3.0L-T .28/5.0/.25/.06/.44 E Passed 9,495

NTK3.0T5FCC3

20-Sep 1992 Mercedes 5.0L .23/1.8/.20/.04/.30 F Passed 4,628

NMB5.0V5FA10

13-Sep 1992 Nissan 2.4L .18/3.3/.18/.04/.59 K Passed 6,635

NNS2.4V5FAAX

06-Sep 1992 Honda 1.8L .26/5.5/.23/.09/.24 K Passed 9,869

NHN1.8V5FXC9

23-Aug 1992 General Motors 4.3L-T .25/3.7/.59/.46/1.10 O Passed 5,236

N3G4.3TBXE31

23-Aug 1992 General Motors 4.3L-T .27/4.4/.71/.27/.42 N Failed - Recall Pending 18,474

N3G4.3TBXEB2

09-Aug 1992 Chrysler 5.2L-T .27/6.2/.59/.49/1.07 E Passed 6,393

NCR5.2T5FHB4

02-Aug 1992 Chrysler 4.0L-T .20/3.6/.20/.15/.90 N Passed 16,578

NCR242T5FEFX

26-Jul 1992 Ford 1.9L .12/2.80/.23/.08/1.3 K Passed 16,681

NFM1.9V5FCC0

26-Jul 1992 Ford 4.9L-T .39/2.50/.74/.89/.40 E Passed 10,040

NFM4.9T5HGL6

19-Jul 1992 Volkswagen 1.8L .20/3.5/.47/.56/.68 F Passed 7,531

NVW1.8V5GWM9

12-Jul 1992 Ford 5.8L-T .23/2.20/.73/.65/.70 E Passed 22,116

NFM5.8T5HAL7

12-Jul 1992 Ford 2.3L-T .34/4.40/.35/.12/.80 N Passed 12,366

NFM2.3T5FML8

06-Jul 1992 Hyundai 1.5L .28/3.1/.20/.09/.51 F Passed 7,018

NHY1.5V5FCA8

21-Jun 1992 Ford 3.8L .16/1.90/.19/.03/1.2 K Passed 40,930

NFM3.8V5FJC6

21-Jun 1992 Ford 2.3L .16/2.10/.10/.02/.20 K Passed 5,904

NFM2.3V5FYC4

20-Jun 1992 Isuzu 3.1L-T .49/12.5/.67/.49/.89 E Failed - Recall Pending 6,789

NSZ3.1T5FKB4

Page 8

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

14-Jun 1991 Chrysler 2.5L-T .19/6.1/.16/.05/.62 N Passed 5,267

MCR150T5FDV4

07-Jun 1991 General Motors 3.8L .15/2.6/.21/.12/.68 K Passed 4,000

M2G3.8W8JAW8

24-May 1991 Chrysler 3.3L-T .31/4.1/.56/.xx/.36 E Passed 21,632

MCR3.3T5FBRX

10-May 1991 General Motors 4.3L-T .72/8.1/.83/.37/.53 E Failed - Recalled 17,855

M3G4.3T5TAA3

02-May 1991 Ford 2.3L .19/4.3/.35/.18/.30 K Passed 28,558

MFM2.3V5FWCX

26-Apr 1991 Ford 4.0L-T .19/3.60/.43/.24/1.7 E Passed 7,979

MFM4.0T5FACX

19-Apr 1991 Ford 5.8L-T .37/5.9/.86/.66/.49 E Passed 19,863

MFM5.8T5HAL6

12-Apr 1991 Chrysler 5.9L-T .42/4.1/.86/.78/.53 E Passed 8,145

MCR5.9T5HGD7

05-Apr 1991 General Motors 4.9L .27/6.0/.37/.20/.33 K Passed 23,813

M2G4.9W8XTA6

21-Mar 1991 BMW 1.8L .20/2.2/.19/.06/.27 K Passed 5,546

MBM1.8V5F4V1

14-Mar 1991 Toyota 3.0L-T .18/2.3/.25/.12/.30 E Passed 20,219

MTY3.0T5FBE1

07-Mar 1991 Mercedes 3.0L .12/1.40/.12/.16/.63 F Passed 9,049

MMB3.0V6FA19

01-Mar 1991 Mitsubishi 2.4L-T .20/2.80/.21/.47/.54 N Passed 6,726

MMT2.4T5FC12

22-Feb 1991 Ford 2.2L .16/2.90/.13/.02/.28 K Passed 4,891

MFM2.2V5FZCX

15-Feb 1991 Ford 4.0L-T .18/3.40/.31/.30/1.6 E Passed 42,893

MFM4.0T5FAM0

08-Feb 1991 Ford 2.3L-T .25/3.60/.26/.13/1.00 N Passed 7,008

MFM2.3T5FML7

25-Jan 1991 Mitsubishi 1.5L .26/2.40/.29/.05/.57 K Passed 9,376

MMT1.5V5FC42

18-Jan 1991 Volvo 2.3L .21/2.40/.18/.05/.60 F Passed 7,957

MVV2.3V5FE81

11-Jan 1991 Mazda 1.6L .25/2.90/.31/.22/.22 K Passed 8,213

MTK1.6V5FCS9

04-Jan 1991 Isuzu 1.6L .23/3.70/.21/.33/.24 F Passed 9,141

MSZ1.6V5FCEX

1993

07-Dec 1991 Nissan 1.6L .21/4.50/.27/.06/.67 K Passed 27,337

MNS1.6V5FAA2

30-Nov 1991 Mitsubishi 3.0L .23/2.70/.67/.69/5.16 G Failed - Recalled 3,219

MMT3.0V5FC28

16-Nov 1991 Toyota 2.5L .16/1.40/.26/.10/.25 K Passed 17,605

MTY2.5V5FCC0

09-Nov 1991 Saab 2.3L .21/2.30/.22/.18/1.78 F Passed 2,036

MSA2.3V5FNA5

02-Nov 1991 Chrysler 4.0L-T .26/4.50/.19/.17/.59 N Passed - Evaporative System 22,279

MCR242T5FEF9 Defects - Recalled

26-Oct 1991 Honda 1.6L .23/3.70/.40/.42/.24 K Passed 6,825

MHN1.6V5FVC3

19-Oct 1991 Ford 1.9L .15/3.30/.21/.23/1.00 K Passed 38,725

MFM1.9V5FAC6

12-Oct 1991 Ford 3.8L .16/3.30/.27/.11/.13 K Passed 33,593

MFM3.8V5FXC6

Page 9

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

05-Oct 1991 Ford 4.6L .21/4.50/.36/.43/.56 K Passed 14,259

MFM4.6V5FDC7

28-Sep 1991 Ford 5.0L .22/1.90/.38/.11/1.75 K Passed 5,772

MFM5.0V5HBH8

21-Sep 1991 Hyundai 1.5L .28/2.39/.21/.07/.18 K Passed 14,425

MHY1.5V5FCA7

14-Sep 1991 Nissan 2.4L .18/3.30/.24/.06/.70 K Passed 7,627

MNS2.4V5FAA9

07-Sep 1991 General Motors 4.3L-T .47/9.10/.34/.--/.-- E Marginal Failure - No Recall 30,740

M3G4.3T5XEB2 (>3751lbs)

07-Sep 1991 General Motors 4.3L-T .53/10.8/.27/.08/.32 N No Decision 30,740

M3G4.3T5XEB2 (<3751lbs)

31-Aug 1991 VW 1.8L .25/3.30/.40/.24/.38 F Passed 6,103

MVW1.8V5FWM8

17-Aug 1990 General Motors 4.3L-T .64/7.70/.91/.50/.44 E No Decision 20,202

L3G4.3T5TAA2

03-Aug 1990 Chrysler 2.2/2.5L .19/5.50/.30/.12/.99 K Passed 16,688

LCR2.5V5FCEX

20-Jul 1991 Ford 1.8L .21/2.40/.40/.28/.72 K Passed 9,297

MFM1.8V5FXC1

13-Jul 1991 Ford 5.0L .16/3.30/.18/.06/1.73 A Passed 4,637

MFM5.0V5FXC7

06-Jul 1991 Suzuki 1.0L .28/3.70/.18/.05/.59 F Passed 10,541

MSK1.0V5FFC3

22-Jun 1990 Mazda 3.0L-T .25/9.90/.42/.20/.29 E Passed 9,819

LTK3.0T5FCC1

15-Jun 1990 Isuzu 1.6L .29/4.80/.29/.19/.22 F Passed 10,264

LSZ1.6V5FHA4

07-Jun 1990 General Motors 3.1L .33/4.70/.30/.14/.44 K Passed 43,822

L1G3.1W8XGZX

01-Jun 1990 General Motors 2.2L .20/4.00/.40/.15/.47 K Passed 19,828

L1G2.2W5JFG7

24-May 1990 NUMMI 1.6L .15/1.20/.18/.10/.18 K Passed 16,030

LNT1.6V5FCD6

18-May 1990 Ford 3.0L .35/6.70/.52/.24/.18 K Passed 9,255

LFM3.0V5FXD2

10-May 1990 Honda 2.2L .16/2.90/.21/.05/.19 K Passed 29,342

LHN2.2V5FFCX

29-Jun 1990 Mitsubishi 2.0L .24/2.80/.22/.20/1.42 K Passed 6,751

LMT2.0V5FC19

03-May 1990 Ford 5.8L-T .53/7.20/.78/.41/.70 E Marginal Fail-No Recall 28,080

LFM5.8T5HAC5

26-Apr 1990 Toyota 4.0L .16/1.20/.22/.04/.45 K Passed 11,985

LTY4.0V5FCC7

19-Apr 1990 Ford 3.8L .20/4.10/.31/.08/.15 K Passed 6,194

LFM3.8V5FFC3

13-Apr 1990 Mitsubishi 1.5L .23/2.35/.23/.16/.34 F Passed 4,422

LMT1.5V5FC19

12-Apr 1990 Mazda 1.8L .23/2.90/.34/.11/.18 K Passed 4,156

LTK1.8V5FCE1

05-Apr 1990 BMW 2.5L .23/3.50/.19/.07/.35 F Passed 4,422

LBM2.5V5F35X

29-Mar 1990 AMC (Chry) 4.0L-T .30/5.10/.28/.12/.72 C Passed- ECS Defects 4,439

LAM242T5LND9 Recalled

15-Mar 1990 General Motors 4.3L-T .64/14.4/.35/.13/.30 E/N No Decision 9,262

L3G4.3T5XEB1

22-Mar 1990 General Motors 4.5L .37/7.30/.49/.22/.22 K Marginal Fail-No Recall 27,209

L2G4.5W8X5G2

Page 10

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

02-Mar 1990 Diamond Star 1.8L .22/1.76/.18/.07/.40 K Passed 8,424

LDS1.8V5FC17

01-Mar 1990 Nissan 3.0L-T .20/2.10/.56/1.30/.66 E Passed 5,478

LNS3.0T5FDC1

23-Feb 1990 Ford 2.9L-T .30/4.00/.24/.15/--- C Passed 12,595

LFM2.9T5FRD9

22-Feb 1990 Subaru 2.2L .17/2.00/.36/.22/.23 F Passed 7,654

LFJ2.2V5FCD4

08-Feb 1990 Mitsubishi 2.4L-T .19/3.00/.33/.23/.44 C Passed 6,043

LMT2.4T5FC11

01-Feb 1990 Ford 5.0L .39/1.40/.90/---/.21 G Passed 11,941

LFM5.0V5HBG6

20-Jan 1990 Ford 3.8L .30/3.00/.33/.21/1.96 K Passed 8,708

LFM3.8V5FAC4

12-Jan 1990 Chrysler 5.9L-T .49/4.50/1.19/1.33/.42 E Failed-Recalled 12,616

LCR5.9T5HGD6

04-Jan 1990 AMC (Chry) 4.2L-T .52/13.35/.70/.64/1.45 C Failed-Recalled 22,064

LAM258T2HEA8

1992

14-Dec 1990 Toyota 2.4L-T .10/1.30/.25/.12/.23 N Passed 20,924

LTY2.4T5FCC5

01-Dec 1990 Diamond Star 2.0L .24/3.32/.43/.35/.66 K Passed 8,371

LDS2.0V5FC21

30-Nov 1990 Hyundai 1.5L .39/3.81/.22/.10/.31 F Passed 16,779

LHY1.5V5FCA6

16-Nov 1990 Nissan 2.4 .18/3.84/.28/.06/.79 K Passed 9,593

LNS2.4V5FACX

02-Nov 1990 General Motors 2.0L .19/3.20/.39/.14/.55 K Passed 5,270

L1G2.0W5JFH7

02-Nov 1990 Ford 1.9L .17/6.10/.52/.27/.xx K Passed 11,741

LFM1.9V5FFH9

26-Oct 1990 Chrysler 3.3L .32/3.84/.55/.26/.45 K Passed 10,315

LCR3.3V5FCF7

19-Oct 1990 Ford 4.0L-T .17/4.36/.42/.00/1.68 E Passed 10,315

LFM4.0T5FAC9

13-Oct 1989 General Motors 5.7L .29/2.12/.55/.xx/.64 G Passed-Evap. Defects 4,501

K1G5.7V8DCA9 Recalled

28-Sep 1989 AMC (Chry) 2.5L-T .29/8.81/.69/.--/.51 C Failed-Recalled 4,441

KAM150T5LAD9

08-Sep 1990 Ford 2.3L .23/4.98/.28/.14/.17 K Passed 26,227

LFM2.3V5FXC0

24-Aug 1990 Ford 1.9L .25/6.76/.67/.30/.23 K Failed-Recalled 19,900

LFM1.9V5FFC4

27-Jul 1990 Ford 2.3L-T .30/6.25/.32/.34/1.41 N Passed 9,061

LFM2.3T5FMC6

13-Jul 1990 Ford 1.9L (GT) .34/3.77/.85/.56/.27 A Failed-Recalled 5,461

LFM1.9V5HMC6

03-Feb 1989 Mitsubishi 2.0L .22/2.14/.19/.05/1.29 K Passed 7,618

KMT2.0V5FC18

27-Jan 1989 Mitsubishi 2.0L-T .23/3.88/.78/1.17/.83 C Passed 9,171

KMT2.0T2FB16

06-Jan 1989 BMW 2.5L .26/2.71/.20/.10/.73 B Passed 15,000

KBM2.5V5F359

1991

02-Dec 1989 Ford 2.9L-T .25/5.79/.26/.23/.18 N Passed 18,467

KFM2.9T5FRD8

Page 11

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

12-Nov 1989 Ford 3.8L .34/3.84/.27/.06/- K Passed 35,933

KFM3.8V5FFC2

21-Oct 1989 Volvo .21/2.43/.19/.08/.71 F Passed 15,762

KVV2.3V5FE8X

10-Oct 1989 Isuzu 2.6L-T .37/7.24/.39/.35/.33 M Passed 4,243

KSZ156T5FGA8

30-Sep 1989 General Motors 3.8L .19/1.65/.23/.10/.27 F Passed 30,453

K3G3.8W8XEB6

19-Sep 1989 General Motors 7.4L-T .28/8.26/.75/.34/.60 L Passed 10,926

KGC7.4T5HAC8

19-Sep 1989 Ford 5.8L-T .41/4.04/.82/1.58/.66 E Passed 16,542

KFM5.8T5HAC4

09-Sep 1989 Ford 1.6L .15/3.74/.27/.09/.14 A Passed 6,515

KFM1.6V5FXC9

29-Aug 1989 Ford 2.9L-T .26/6.27/.26/.38/.75 E Passed 8,510

KFM2.9T5FRC7

19-Aug 1989 Ford 2.2L .23/4.88/.14/.01/.26 K Passed 4,685

KFM2.2V5FXC4

08-Aug 1989 Ford 3.8L .37/3.43/.38/.44/1.82 K Passed 25,012

KFM3.8V5FAC3

29-Jul 1989 Ford 3.0L .28/4.50/.52/.28/.49 C Passed 30,118

KFM3.0V5FED8

18-Jul 1989 Hyundai 2.4L .29/2.86/.25/.10/.74 F Passed 8,075

KHY2.4V5FCDX

08-Jul 1989 Toyota 2.2L-T .16/2.75/.44/.35/.34 C Passed 4,443

KTY2.2T5FBB0

24-Jun 1988 Chrysler 2.2L .25/4.06/.48/.35/.30 A Passed 11,025

JCR2.2V5FAD7

13-Jun 1989 AMC (Chry) 4.0L-T .41/7.33/.37/.39/1.11 C Marginal Fail-No Recall 30,032

KAM242T5LND8

03-Jun 1988 Honda 1.5L .15/3.29/.61/.37/.20 A Passed 32,991

JHN1.5V5FDC3

23-May 1988 Ford 3.0L-T .28/6.08/.46/.19/1.82 C Passed 21,182

JFM3.0T5FEC7

13-May 1988 Ford 2.9L-T .39/6.76/.43/.55/.45 C Passed 25,318

JFM2.9T5FRC6

02-May 1988 Ford 2.3L .30/4.24/.34/.44/.30 A Passed 5,144

JFM2.3V5FGK8

22-Apr 1988 Chrysler 3.0L .38/2.85/.41/.25/.45 A Passed 9,487

JCR3.0V5FBRX

26-Mar 1988 General Motors 2.8L-T .39/9.13/.44/.28/.52 E Marginal Fail-No Recall 8,865

J3G2.8T5XAS5

21-Mar 1988 Nissan 1.6L .21/4.43/.32/.06/.68 A Passed 28,350

JNS1.6V5FDC7

12-Mar 1988 Volkswagen 1.8L .21/1.84/.41/.21/.86 B Passed 15,017

JVW1.8V6F9A1

28-Feb 1988 Ford 1.9L .24/6.80/.78/.34/.27 A Marginal Fail-No Recall 30,140

JFM1.9V5FFC2

19-Feb 1988 Ford 2.3L-T .54/5.53/.72/.30/.23 E Failed-Recalled 21,955

JFM2.3T5FFG1

06-Feb 1988 Ford 3.8L .39/2.52/1.16/.80/3.78 A Failed-Recalled 17,999

JFM3.8V5FFC1

28-Jan 1988 Mitsubishi 1.5L .29/6.22/.48/.08/.91 A Passed 12,461

JMT1.5V2FCC8

16-Jan 1988 General Motors 4.3L-T .42/5.42/.93/.41/.50 E Passed 18,028

J3G4.3T5TAA0

Page 12

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

07-Jan 1988 BMW 2.7L .30/2.99/.23/.22/.57 B Passed 19,226

JBM2.7V5F359

1990

10-Dec 1988 Toyota 1.5L .22/3.77/.37/.11/.40 A Passed 20,947

JTY1.5V1FCC6

26-Nov 1988 Ford 1.9L .37/3.50/.98/.72/.24 A Failed-Recalled 11,218

JFM1.9V5HMK3

13-Nov 1988 Ford 2.3L .28/3.71/.88/.62/.38 A Failed-Recalled 32,094

JFM2.3V5HEH5

29-Oct 1988 Jaguar 3.6L .18/2.68/.28/.19/.73 B Passed 4,667

JJR3.6V5FLH5

18-Oct 1988 Mercedes 3.0L .31/3.0/.29/.15/.3 B Passed 8,123

JMB3.0V6FA16

09-Oct 1988 Mitsubishi 2.6L-T .24/7.03/.56/.77/1.21 C Passed 9,196

JMT2.6T2FBCX

26-Sep 1988 General Motors 2.3L .17/1.87/.26/.14/.29 A Passed 7,807

J2G2.3W8XEW4

19-Sep 1988 AMC (Chry) 4.0L-T .28/4.96/2.47/3.32/1.21 C Failed-Recalled 25,051

JAM242T5LND7

10-Sep 1988 Chrysler 3.9L-T .43/3.26/.79/.39/.70 J Passed 6,524

JCR3.9T5HFM8

30-Aug 1988 Daihatsu 1.0L .20/3.44/.26/.25/.29 F Passed 5,172

JDH1.0V5FCB1

27-Aug 1988 Suzuki 1.3L-T .18/5.40/.55/.86/1.03 I Passed 80,142

JSK1.3T2FFC7

09-Aug 1988 Isuzu 2.6L-T .34/7.33/.84/1.08/.38 E Passed 6,186

JSZ156T5FBB9

31-Jul 1988 Ford 1.3L .15/2.88/.60/.50/1.18 A Passed-EGR Sensor Defect 16,313

JFM1.3V2FZC4 Recalled

23-Jul 1988 Ford 5.8L-T .48/6.09/.79/1.10/.55 E Passed 22,919

JFM5.8T5HAC3

09-Jul 1988 Mazda 2.2L .15/2.39/.21/.03/.20 A Passed 12,433

JTK2.2V5FCH7

28-Jun 1988 Mitsubishi 2.0L-T .30/3.78/.77/1.26/.88 C Passed 20,355

JMT2.0T2FBC7

20-Jun 1988 Yugo 1.3L .xx/x.xx/.xx/.xx/.xx B No Decision 11,425

JYA1.3V2GAA4 Insufficient Sample

11-Jun 1988 Hyundai 1.5L .23/6.63/.24/.10/.58 B Passed 83,072

JHY1.5V2FCB4

31-May 1987 General Motors 5.7L-T .41/3.42/.79/.48/.67 E Passed 16,369

H3G5.7T5TYA9

21-May 1987 General Motors 5.0L .27/3.87/.58/.41/1.34 A Passed 13,999

H2G5.0W4NBA6

10-May 1987 Chrysler 2.6L-T .21/7.89/.92/1.13/1.65 C Passed 9,032

HCR2.6T2BAP7

30-Apr 1987 BMW 2.5L .34/2.72/.29/.27/.78 B Passed 13,255

HBM2.5V5F354

19-Apr 1987 BMW 3.4L .29/3.59/.44/.18/1.98 B Passed 6,505

HBM3.4V5F571

09-Apr 1987 Nissan 3.0L .32/2.61/.57/.29/.90 A Passed 38,082

HNS3.0V5FACX

29-Mar 1987 Toyota 3.0L .19/1.52/.40/.07/.22 A Passed 6,460

HTY3.0V5FBB1

19-Mar 1987 Ford 2.3L .61/5.06/.68/.48/.14 A Failed-Recalled 6,889

HFM2.3V5FFG7

13-Mar 1987 Ford 5.0L-T .44/3.16/.91/1.82/.62 E Passed-Evap Defect 17,361

HFM5.0T5HAGX Recalled

Page 13

IN-USE VEHICLE COMPLIANCE TESTING SUMMARY Updated 1-21-2001

Test Model Manufacturer Average Standards

Date Year Engine Family HC/CO/NOx/HyNOx/Evap Code* Status Production

26-Feb 1987 Mitsubishi 2.4L-T .30/2.05/.69/.74/3.33 C Failed-Recalled 8,094

HMT2.4T5FBD7

13-Feb 1987 Volkswagen 1.8L .15/1.64/.25/.10/.93 B Passed 11,594

HVW1.8V6FAC5

01-Feb 1987 Subaru 1.8L-T .20/3.24/.33/.16/.32 D Passed-Cat Defect 5,878

HFJ1.8T5HCR5 Recalled

18-Jan 1987 AMC (Chry) 4.2L-T .56/9.31/1.37/1.01/1.43 C Failed-Recalled 5,022

HAM258T2HEA2

03-Jan 1987 Chrysler 3.9L-T .41/6.74/.82/.57/1.5 C Marginal Fail-No Recall 7,078

HCR3.9T2HFR8

1989

04-Dec 1987 General Motors 3.8L .22/1.99/.51/.19/.42 B Passed 51,462

H2G3.8V8XEB7

13-Nov 1987 General Motors 2.8L .27/2.81/.47/.41/1.1 A Passed 40,758

H1G2.8W8XRZ9

25-Oct 1987 BMW 2.7L .30/3.75/.86/.36/.81 B Failed-Recalled ~7,200

HBM2.7V5F300

11-Oct 1987 Ford 4.9L-T .62/3.48/.77/.79/.75 E Failed-Recalled 12,594

HFM4.9T5HGG2

27-Sep 1987 Ford 5.0L .35/1.18/.71/.34/.45 A Passed 40,003

HFM5.0V5HBC7

13-Sep 1987 Honda 2.5L .18/1.77/.48/.39/.13 A Passed 12,640

HHN2.5V5FZC6

30-Aug 1987 Nissan 1.6L .11/4.67/.26/.14/1.1 A Passed 64,461

HNS1.6V9FAC2

21-Aug 1987 NUMMI 1.6L .24/5.17/.56/.35/1.2 A Passed 21,395

HNT1.6V2FCC9

02-Aug 1987 Mitsubishi 1.5L .32/4.92/.66/.33/.83 A Passed 16,139

HMT1.5V2FCD5

19-Jul 1987 Mitsubishi 2.0L-T .25/3.53/.79/1.2/.9 C Passed 14,752

HMT2.0T2FBD4

05-Jul 1987 AMC (Chry) 4.0L-T .25/2.89/1.65/1.9/1.8 C Failed-Recalled ~19,121

HAM242T5LAB4

19-Jun 1987 Chrysler 2.2L .18/1.7/.56/.36/.2 A Passed 26,367

HCR2.2V5FAD3

05-Jun 1987 Volvo 2.3L-Turbo .19/2.3/.30/.15/.95 B Passed 5,991

HVV2.3V5FFT2

22-May 1987 Ford 2.9L-T .42/6.9/.74/.9/.33 C Marginal Fail-No Recall 35,380

HFM2.9T5FCR2

15-May 1986 General Motors 4.3L-T .47/9.7/.63/.7/.63 E Marginal Fail-No Recall 15,917

G1G4.3T5TAA8

01-May 1986 Ford 3.8L .50/4.28/.57/.42/.34 A Failed-Recalled 37,949

GFM3.8V5HHC6

01-May 1987 Suzuki 1.0L .17/2.57/.28/.16/.55 B Passed 34,695

HSX1.0V2FFC6